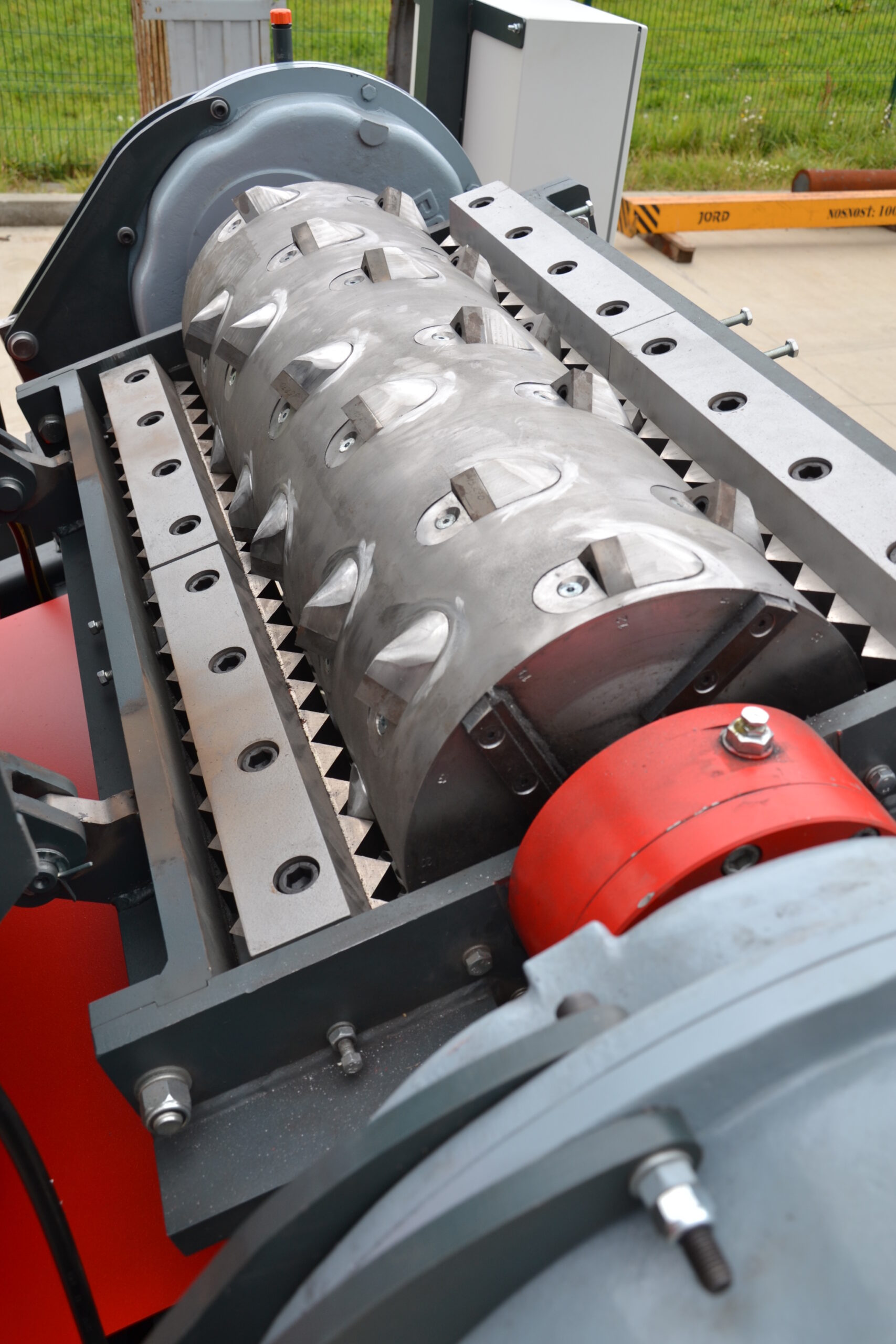

UNIQUE AND ADVANTAGES OF THE CASTOR CONCEPT – Part 2/2

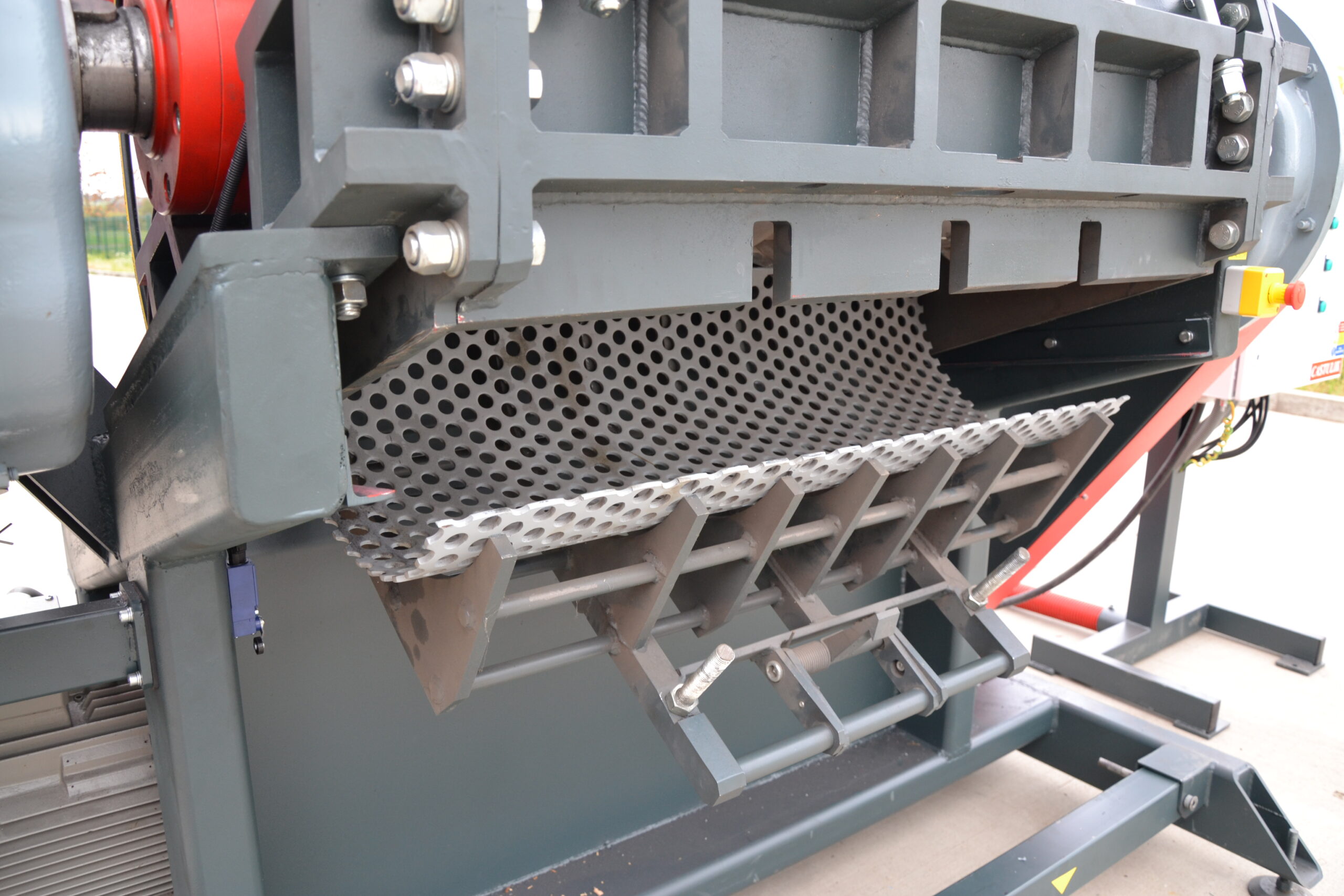

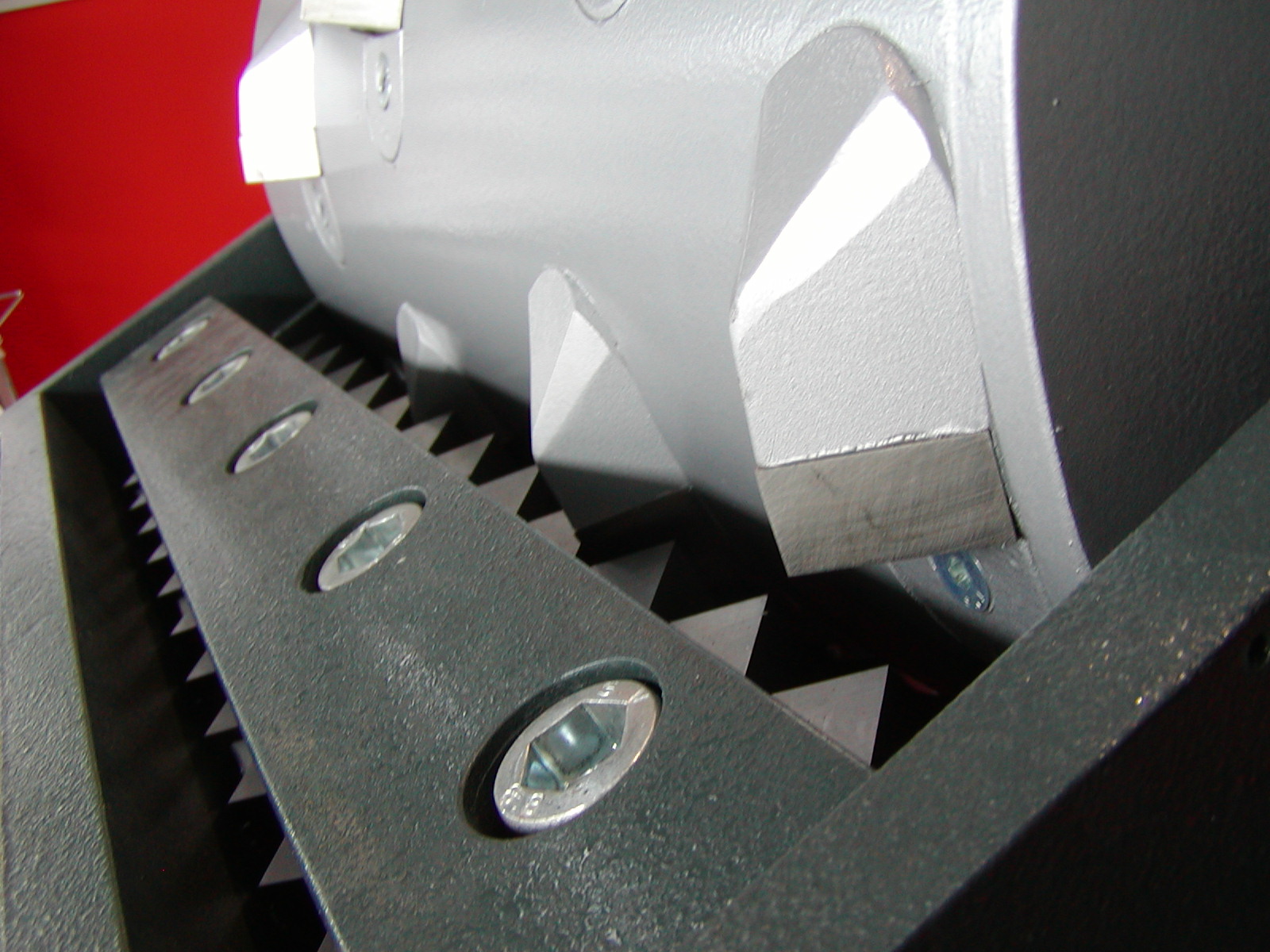

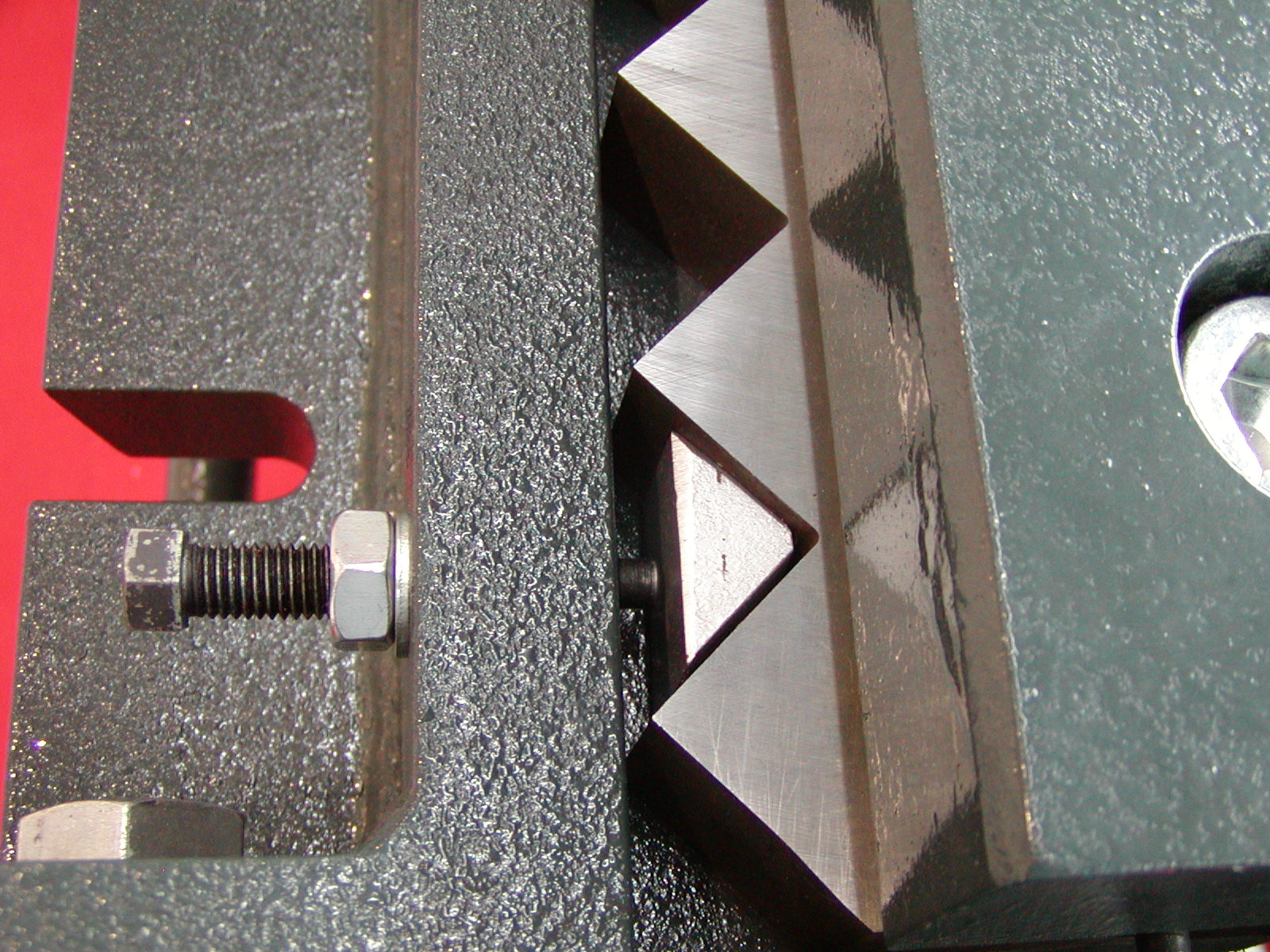

The CASTOR single rotor shredder has a unique stator blade arrangement of two, equivalent rotor blades in the shredding chamber so that each rotor blade makes two cuts in one rotor revolution. The radially adjustable position of the stator blades and the perfect geometry of the stator and rotor blades have a positive effect on the performance of the crusher and the overall efficiency of the crushing process. In addition, thanks to this design CASTOR can also crush without a sieve.

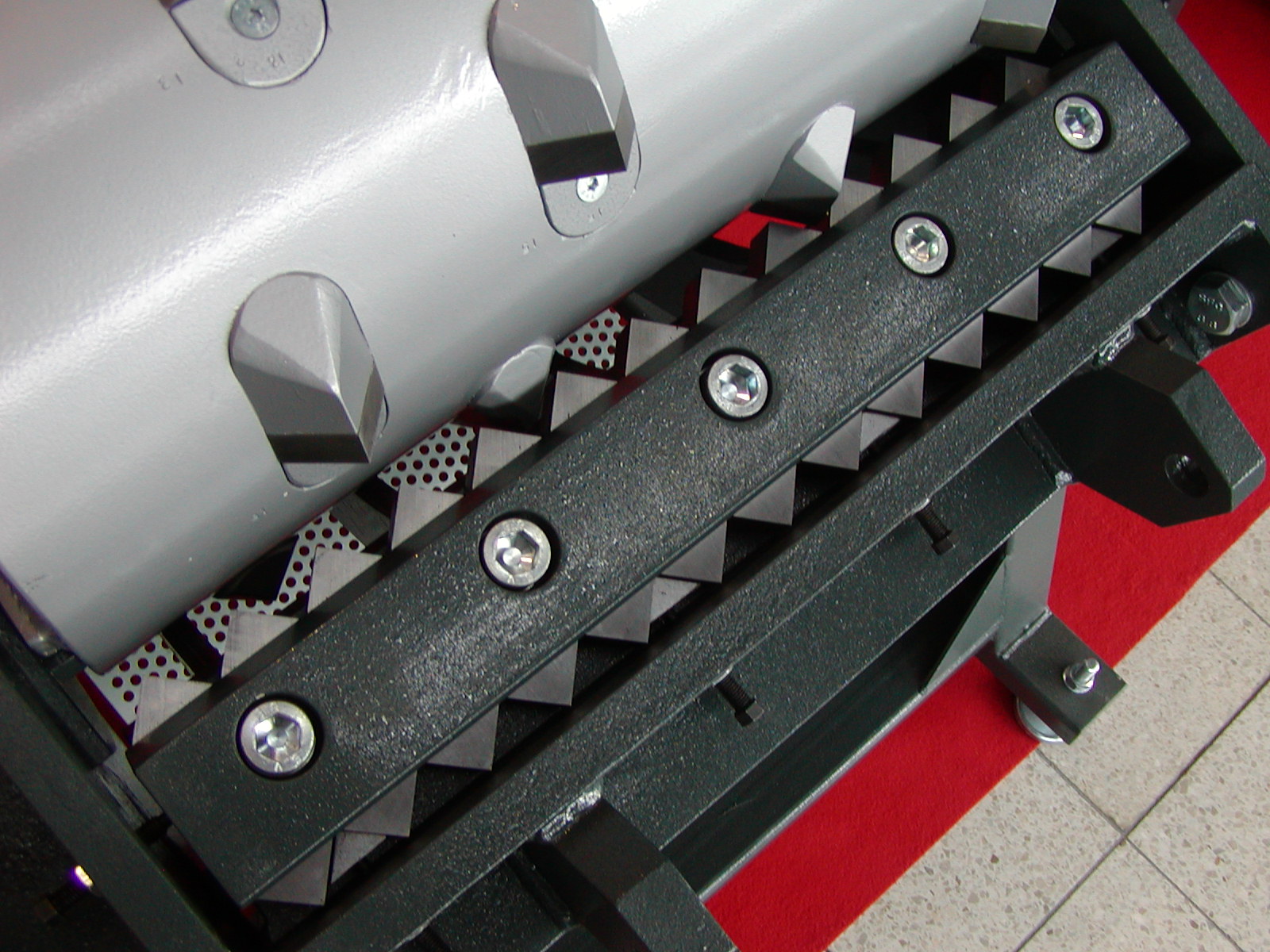

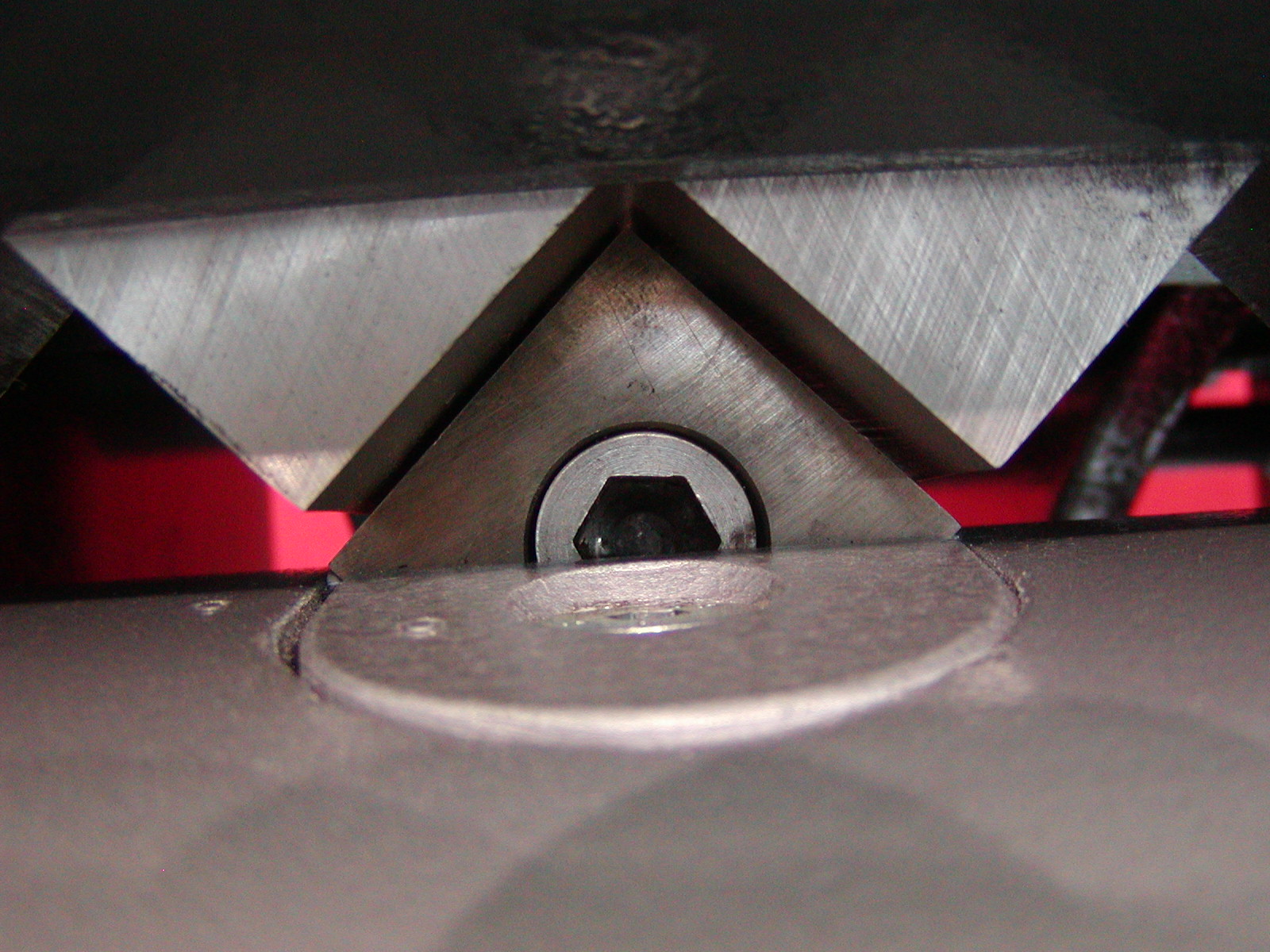

Each rotor blade has the shape of a double-sided ridge. This original solution gives the user additional added value, as he has four stator knife blades at his disposal instead of the usual two.

The rotor plates can be rotated around two axes. The user thus has 4 rotor knife blades at his disposal.