SG400-0-0340

SG400/600_30kW

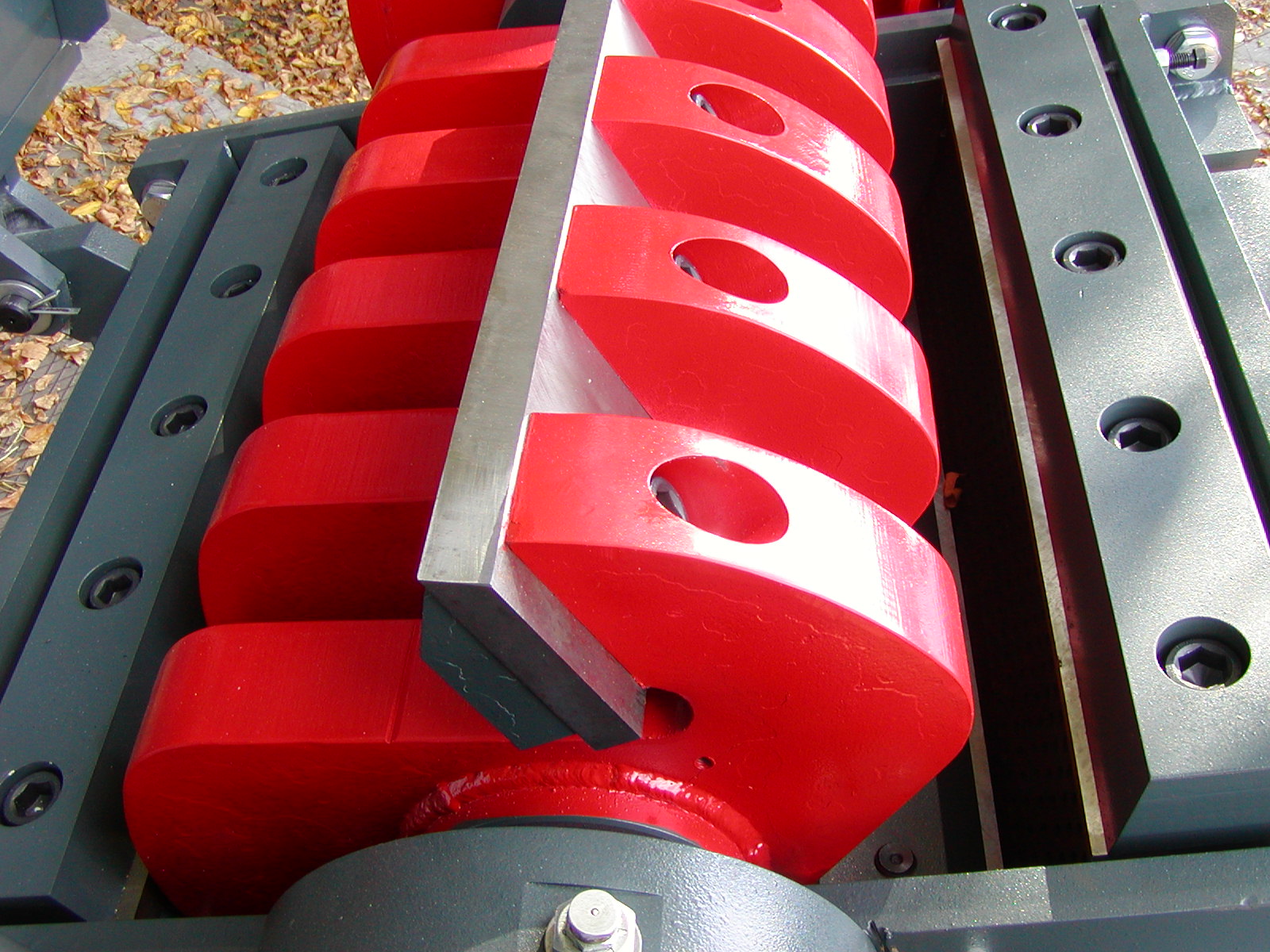

Knife mill

Rotor diameter

400 mm

Length of blades

600 mm

Number of stator blades

2

Number of rotor blades

3 alt. 5

Rotor speed

900

Screen openings

min. 2 mm

Control system

PLC

Electric motor power input

22 kW alt. 30 kW alt. 45 kW

Weight of the device

2000 kg

The tip

for pneumatic transport DN150

Funnel

with noise protection

Flywheel

Yes

Option

hopper box alt. on conveyor

The SG400 knife mill is one of the most sophisticated machines of its kind on the market. The robust crushing chamber assembled from four heavy machined weldments not only gives the machine a high operating factor but also gives the user the possibility of its partial refurbishment or repair in case of wear by abrasion or in case of intrusion of disturbing materials. The method of storing and fixing the blades, the sieve, opening the hopper and adjusting the blades gives the user additional added value. The electronic control system allowing the control of the peripheral devices of the shredder makes this machine a sophisticated tool for the disintegration system of a wide range of materials.