MN300-1-0159

MN300/400_15kW

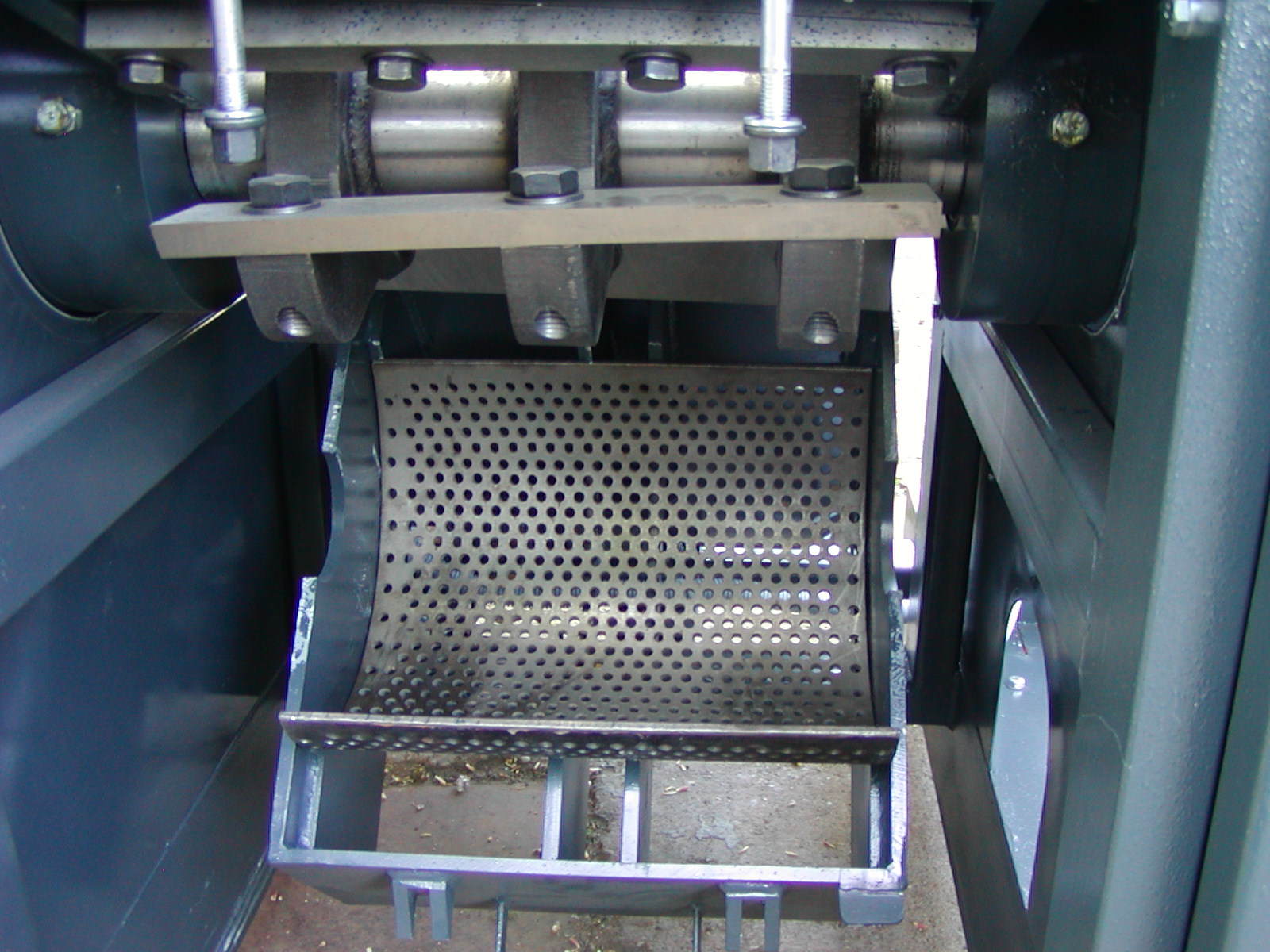

Knife mill

Rotor diameter

300 mm

Length of blades

400 mm

Number of stator blades

2

Number of rotor blades

3 alt. 5

Rotor speed

900

Screen openings

min. 2 mm

Control system

manual alt. PLC

Electric motor power input

7,5 alt. 15 alt. 22 kW

Weight of the device

720 - 800 kg

The tip

for pneumatic transport DN150

Funnel

with noise protection

Flywheel

Yes

Option

hopper box alt. on conveyor

The crushing of the material in the knife mill takes place on the straight blades of the working tools, which are located on the rotor and stator of the machine. A sieve under the rotor orbit is used to define the size of the required fraction of the output of the crushing plant. The sieve holes can have apertures as small as 0.5 mm in diameter according to customer specifications. The most commonly used holes are 10 mm in diameter. This type of crusher allows a wide range of materials to be crushed. This includes plastics, rubber, cables, leather, bone and horn. It has also proved its worth in shredding wood, forest chips, straw and paper.