We have developed, manufacture and sell 4 types of crushers in several size ranges. With us you can choose from more than 40 different machines suitable for crushing a wide range of materials.

Choosing the right and suitable crusher is a relatively complex matter. We therefore offer you to visit us at our facility in Stupava and have the issue of disintegration of your material explained on site. At the same time, you will be able to view many of our products in various stages of completion. Any practical tests of the machines must be agreed in advance so that everything is correctly connected and set up in time.

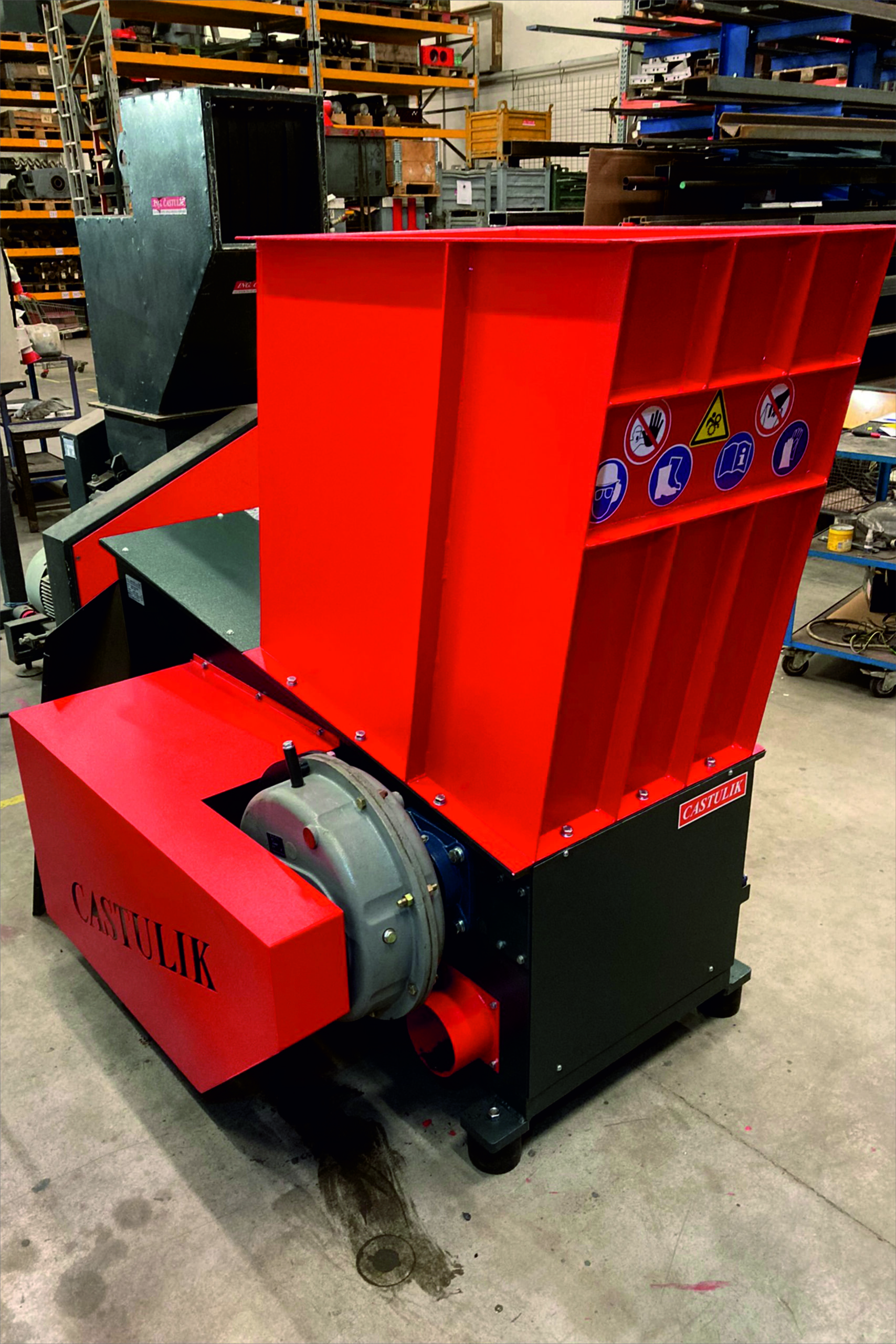

Single-rotor shredders are used for medium-coarse crushing of materials. From the point of view of the rotor rotation frequency, these are medium-speed shredders. The minimum size of the holes in the calibration screen of a single-rotor shredder is 12 mm. PICUS type shredders are designed for light applications such as softwood, polypropylene, cardboard and the like with a usage intensity of 1-2 m3 of waste per day. For more intensive use and heavy applications, the more robust and sophisticated CASTOR model is used. Metal impurities (nails, screws, wires, thin sheets, etc.) in the shredded material are allowed.

Twin-rotor crushers are used for coarse crushing of various materials. They are machines with low speed and high torque. We divide our machines according to the shaft spacing: 120 mm – 160 mm – 240 mm and 340 mm. The size of the output grain depends on the properties of the crushed material and the thickness of the crushing discs. It reaches values of 0-15 mm to 0-200 mm. Smaller crushers can produce smaller grains of crushed material than larger crushers. When choosing the right size of the crusher, it is crucial to assess the size of the crushed objects and the resistance of the material to disintegration (crushing force). Crushing performance plays a secondary role when choosing a machine.

The ARIES four-rotor crusher is constructed from two twin-rotor crushers in a row, the crushing chambers of which are mounted vertically on a common stand (upper crushing stage and lower crushing stage). Both crushing stages are mechanically linked and interconnected by a common control system. The crushed material passes continuously through the upper and lower crushing stages. ARIES crushers are used in medium-fine crushing applications, when there is a requirement for relatively small grain size and at the same time it is inefficient to use single-rotor crushers and knife mills cannot be used.

Knife mills are used for intensive grinding of materials without steel and mineral admixtures into fine-grained powder. The minimum size of the holes in the calibration screen of the knife mill is 0.5 mm. These machines have low torque and high speed. Objects with limited outline dimensions can be inserted into the machine or the material is pre-crushed before entering the mill. Very often, we equip the machine with a loading conveyor and a station for transporting the powder into a big bag. This type of crusher is a bestseller in the plastics processing industry.